Superior 7075 Alloy Steering Rods

There are many reasons to consider fitting heavier-duty or even just upgraded OE-style parts, the most common of these is to regain factory geometry after a lift has been installed. In this situation, aftermarket draglinks and tierods designed for that lift height or those that have added adjustability on the joints are required.

When performance and reliability offroad are what matters most, then a heavy-duty upgraded tie rod and draglink is a definite must! Increasing strength and resistance to bending is essential once larger tyres are fitted. Remember bigger tyre diameter = more leverage and often the weak 1020 grade Hollow factory steering links can"t take the extra load. Upgrading from the Nissan factory 28mm diameter hollow bar to a 35mm Superior Engineering 7075 bar is the perfect choice.

Impact resistance is another huge factor when deciding what to choose. 7075 aluminium has the reputation of being the strongest grade aluminium alloy among many widely used aluminium alloys for various industrial purposes. It delivers a similar level of strength as many steel alloys while also possessing the benefits of easy machinability, corrosion resistance, and a lightweight metal.

The weight saving in upgrading to 7075 steering links helps with reducing loads that need to be dampened by the springs and shocks. Apart from adding to the great look, Anodizing provides surface corrosion protection along with an increase in surface hardness which also helps protect the stunning gold coating and CNC machined logo.

Sometimes, the Tie Rod bar diameter size should be limited as interference with suspension arms and links can occur and lock the steering under full flex. In LandCruisers and Patrols, Tie-rods of approximately 35-36mm diameter allows the perfect amount of clearance for full safe articulation. Caster bushes/plates in conjunction with OE radius arms severely reduce tie rod clearance and in general tie rods approaching 38mm will contact the radius arm under turn/articulation which is extremely dangerous! In this situation, excessive binding will cause the tie rod ends to fail which can be catastrophic.

When changing a tie rod or draglink it is also important to consider the type and configuration of the steering damper. CNC modular Billet style clamp-on steering damper brackets are available to suit most damper styles and configurations and are infinitely adjustable to allow precise fitment.

While 7075 is the Ultimate in light-weight high-strength materials for steering links, you may be the sort of 4WD owner that likes to push the limits in strength. If this is the case, you will want the strongest chromoly steering links in the world, the Superior Engineering 4340M Steering Rods!

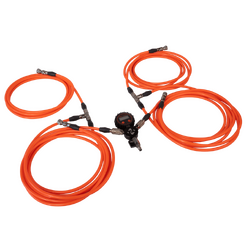

Includes

1 x Superior 7075 Billet Alloy Drag Link Bar

2 x HD Tie Rod Ends (1 x LH & 1 x RH)

1 x Superior

Billet Alloy Taper Pin Damper Bracket Kit

1 x Tie Rod Wedge Tool

Material Comparisons and Technical Data

When selecting materials for an engineering application, critical mechanical properties of the material such are yield strength and tensile strength are considered in the final design.

Yield strength is the maximum stress a material can endure before it begins to permanently deform, not able to return to its original dimensions or shape.

Tensile strength is the maximum tensile stress before a material fails and breaks.

The chart below shows a graphical representation of the yield and tensile strength of an OE Bar against our different products. as you can see the 7075 alloy has a greater tensile strength than both the OE and a greater yield strength than both the OE and our 20MnV6 Hollow bar rods.

Superior Engineering runs FEA testing on all components that we design, the following table shows the results of such testing on an OE spec bar, a 20MnV6 hollow bar and the 7075 alloy bar. it also shows the weight for each bar with the alloy weighing in at barely more than the OE hollow bar whilst being stronger than the 20MnV6 Hollow bar at 1.4kg heavier.

| Material | Diameter | Weight | Yield Strength* |

|---|---|---|---|

| OEM Nissan Hollow Bar | 28.2mm | 2.3kg | 3.500N/m |

| 20MnV6 Hollow Bar | 32mm | 4kg | 4.500N/m |

| 7075-T6 Alloy Solid Bar | 35mm | 2.6 | 5.050N/m |

*FEA Yeild strength tested with a 2 ton Point load in the center of the bar

| SKU | SE-48354 |

|---|---|

| Barcode # | 930000048354 |

| Brand | Superior Engineering |

| Shipping Weight | 7.0000kg |

| Shipping Width | 0.110m |

| Shipping Height | 0.110m |

| Shipping Length | 1.200m |

Superior 7075 Alloy Steering Rods

There are many reasons to consider fitting heavier-duty or even just upgraded OE-style parts, the most common of these is to regain factory geometry after a lift has been installed. In this situation, aftermarket draglinks and tierods designed for that lift height or those that have added adjustability on the joints are required.

When performance and reliability offroad are what matters most, then a heavy-duty upgraded tie rod and draglink is a definite must! Increasing strength and resistance to bending is essential once larger tyres are fitted. Remember bigger tyre diameter = more leverage and often the weak 1020 grade Hollow factory steering links can"t take the extra load. Upgrading from the Nissan factory 28mm diameter hollow bar to a 35mm Superior Engineering 7075 bar is the perfect choice.

Impact resistance is another huge factor when deciding what to choose. 7075 aluminium has the reputation of being the strongest grade aluminium alloy among many widely used aluminium alloys for various industrial purposes. It delivers a similar level of strength as many steel alloys while also possessing the benefits of easy machinability, corrosion resistance, and a lightweight metal.

The weight saving in upgrading to 7075 steering links helps with reducing loads that need to be dampened by the springs and shocks. Apart from adding to the great look, Anodizing provides surface corrosion protection along with an increase in surface hardness which also helps protect the stunning gold coating and CNC machined logo.

Sometimes, the Tie Rod bar diameter size should be limited as interference with suspension arms and links can occur and lock the steering under full flex. In LandCruisers and Patrols, Tie-rods of approximately 35-36mm diameter allows the perfect amount of clearance for full safe articulation. Caster bushes/plates in conjunction with OE radius arms severely reduce tie rod clearance and in general tie rods approaching 38mm will contact the radius arm under turn/articulation which is extremely dangerous! In this situation, excessive binding will cause the tie rod ends to fail which can be catastrophic.

When changing a tie rod or draglink it is also important to consider the type and configuration of the steering damper. CNC modular Billet style clamp-on steering damper brackets are available to suit most damper styles and configurations and are infinitely adjustable to allow precise fitment.

While 7075 is the Ultimate in light-weight high-strength materials for steering links, you may be the sort of 4WD owner that likes to push the limits in strength. If this is the case, you will want the strongest chromoly steering links in the world, the Superior Engineering 4340M Steering Rods!

Includes

1 x Superior 7075 Billet Alloy Drag Link Bar

2 x HD Tie Rod Ends (1 x LH & 1 x RH)

1 x Superior

Billet Alloy Taper Pin Damper Bracket Kit

1 x Tie Rod Wedge Tool

Material Comparisons and Technical Data

When selecting materials for an engineering application, critical mechanical properties of the material such are yield strength and tensile strength are considered in the final design.

Yield strength is the maximum stress a material can endure before it begins to permanently deform, not able to return to its original dimensions or shape.

Tensile strength is the maximum tensile stress before a material fails and breaks.

The chart below shows a graphical representation of the yield and tensile strength of an OE Bar against our different products. as you can see the 7075 alloy has a greater tensile strength than both the OE and a greater yield strength than both the OE and our 20MnV6 Hollow bar rods.

Superior Engineering runs FEA testing on all components that we design, the following table shows the results of such testing on an OE spec bar, a 20MnV6 hollow bar and the 7075 alloy bar. it also shows the weight for each bar with the alloy weighing in at barely more than the OE hollow bar whilst being stronger than the 20MnV6 Hollow bar at 1.4kg heavier.

| Material | Diameter | Weight | Yield Strength* |

|---|---|---|---|

| OEM Nissan Hollow Bar | 28.2mm | 2.3kg | 3.500N/m |

| 20MnV6 Hollow Bar | 32mm | 4kg | 4.500N/m |

| 7075-T6 Alloy Solid Bar | 35mm | 2.6 | 5.050N/m |

*FEA Yeild strength tested with a 2 ton Point load in the center of the bar

| SKU | SE-48354 |

|---|---|

| Barcode # | 930000048354 |

| Brand | Superior Engineering |

| Shipping Weight | 7.0000kg |

| Shipping Width | 0.110m |

| Shipping Height | 0.110m |

| Shipping Length | 1.200m |

More info

More info